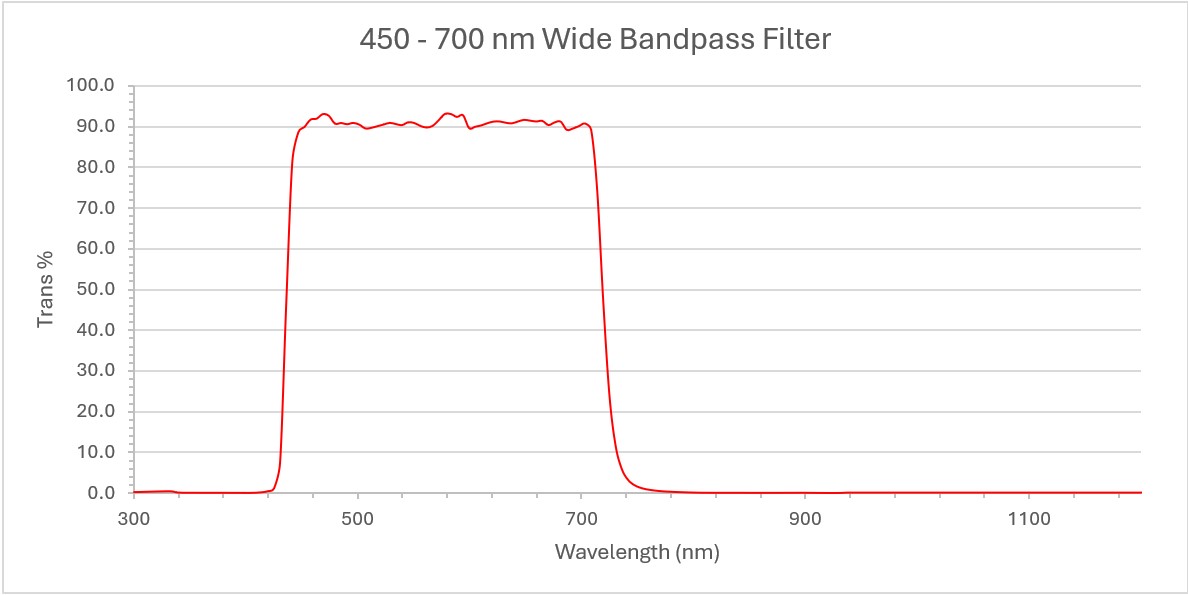

Case Study: 450 - 700nm Wide Band Pass Filter

|

Data Table |

|

|

Specification |

Value |

|

Transmission Band |

450 – 700 nm |

|

Peak Transmission % |

T% >85% |

|

Blocking Range |

300-425, 750 – 1200 nm |

|

Substrate |

GG400 |

|

Dimensions |

25 mm Dia |

|

Thickness |

2.0 mm |

|

Scratch/Dig |

20/10 |

|

Quantity Per Year |

500 |

Case Study: Visible Wide Band Pass Filter with Tight Surface Quality and Durability Specifications

Customer Challenge: A customer required a wide visible bandpass filter that could transmit light in the 450-700 nm range while effectively blocking both ultraviolet (UV) and near-infrared (NIR) wavelengths. The filter was being used with a silicon photodiode detector in a visible camera, hence the wide blocking requirement. The tight surface quality specification was to ensure high quality of the final image.

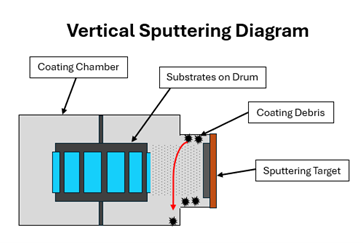

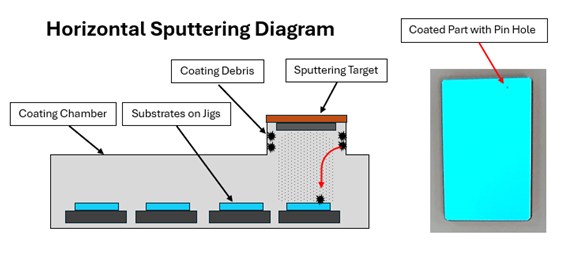

Vortex’s Customised Approach: The high surface quality dictated deposition in a vertically loaded machine as opposed to horizontally loaded machine (compare Fig 1 and 2 below). In horizontally loaded machines (Fig 2), despite regular disciplined housekeeping and maintenance, the most stringent surface quality requirements cannot often be economically attained, so a different approach is required. In 2023 Vortex invested in 2 ‘state-of-the-art’ vertically loaded sputter deposition systems. In this type of machine, the same maintenance and housekeeping disciplines are followed but the additional benefit is that gravity assists achieving high surface quality results, since the substrates are vertically mounted. In the field, the filter could frequently be removed for cleaning by anyone, so had to be durable to handle this, thus a sputtered coating is recommended.

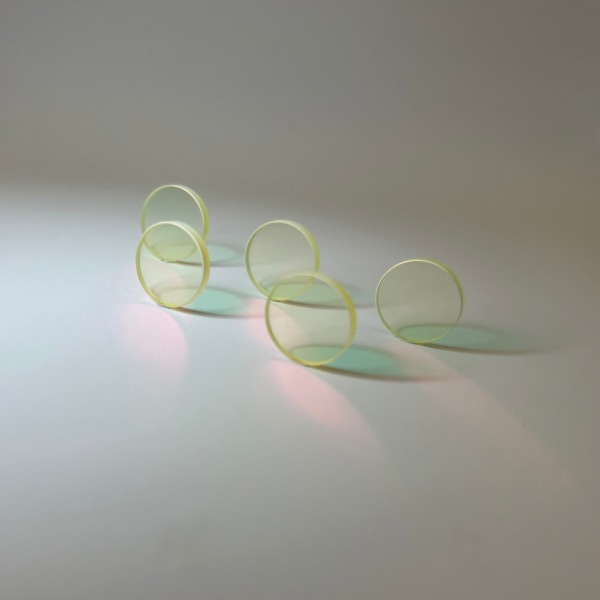

The Outcome: Our vertical sputter coating machines are able to meet high surface quality requirements but also excellent durability and minimal thermal shift, all round a better environmental performance! In this project we were able to meet a challenging range of requirements.