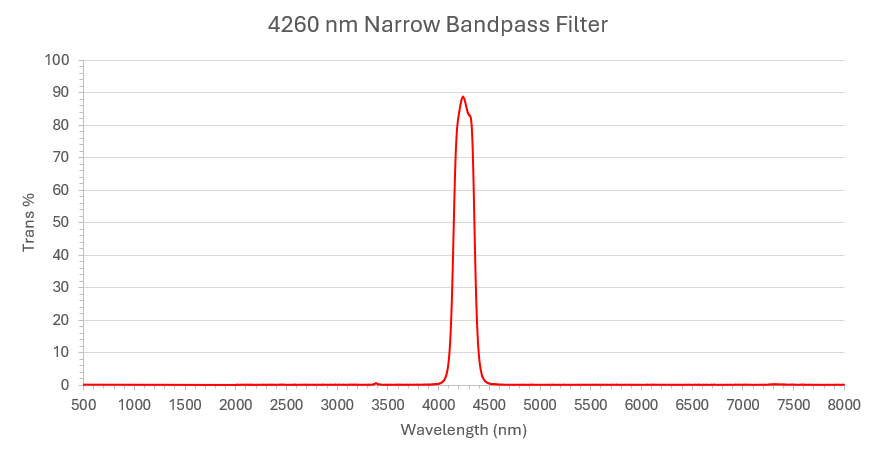

Case Study: 4260 nm Narrow Band Pass

|

Data Table |

|

|

Specification |

Value |

|

Centre Wavelength |

4260 nm +/- 10 |

|

Bandwidth (FWHM) |

220 nm +/- 12 |

|

Peak Transmission |

T% >80% |

|

Blocking Range |

300 – 20000 nm |

|

Substrate |

Sapphire |

|

Dimensions |

4.2 X 4.2 mm |

|

Thickness |

1 mm |

|

Scratch/ Dig |

60/40 |

|

Quantity Per Year |

75000 |

Case Study: High-Volume Production of 4260 nm Centre Wavelength Filter for CO₂ Detection

Customer Challenge: Our customer required 75,000 units per annum of the above 4260 nm filter, the first drop of 1000 within 4 weeks due to a supply chain emergency. The long blocking to > 20µm was needed since the system used a thermopile type detector and this necessitated using a Sapphire substrate. The square filters required edge chips less than 0.1 mm in size. The high volume also demanded an efficient packaging solution, suitable for pick-and-place assembly.

Vortex’s Customised Approach: The optical performance was achieved using our state-of-the-art sputter deposition technology. Dicing Sapphire is difficult but using in-house techniques and experience we have developed technology to meet these stringent edge chip requirements and achieve the < 0.1 mm threshold on a consistent basis. Collectively this approach ensures each filter meets the high-quality standards necessary for accurate CO₂ detection.

Additionally, recognising the importance of efficient production workflows for the customer, Vortex supplied the filters in pick-and-place compatible trays. This packaging solution was specifically needed for ease of handling and integration into the customer’s automated production and assembly lines, thereby enhancing overall efficiency.

The Outcome: Vortex successfully met the critical deadline for the first drop, meaning the customer met theirs! The tight adherence to the optical specification and the high-quality edge profile ensuring the full clear aperture usage within the system resulting in maximum instrument sensitivity and lack of assembly issues during device integration in assembly.

This successful collaboration underscores Vortex’s commitment to innovation and excellence in delivering high-quality, high-volume solutions tailored for onward production. Through listening, active communication and experience Vortex is a reliable partner in supporting advanced product development and manufacturing. We aim to be there in your hour of need!